Chevron leveraging information technology to optimize thermal production of heavy oil with increased recovery and reduced costs

23 June 2011

|

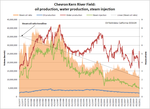

| Chevron’s focus on optimizing the thermal management of the Kern River field has resulted in a steady drop in the steam:oil ratio (barrels steam water per barrel oil), resulting in improved economics of the field even with slowly declining production. Data: California DOGGR. Click to enlarge. |

Chevron, already the largest thermal heavy oil producer, is optimizing thermal production in heavy oil fields by leveraging information technology to improve the percentage recovery as well as the economics. While production costs and refining costs for heavy oil exceed that for light oil, applying information technology solutions for decision-making has provided a significant increase in the margins and profits of operations, according to Chevron engineers in a paper presented on their system earlier this year.

The showcase for Chevron’s efforts—and its international center for heavy oil technology—is the 110-year-old Kern River field in the San Joaquin Valley in California.

Per-well oil production at Kern River is low—the average is 8 barrels of oil per well per day—but there are more than 9,000 production wells in operation in the field. The key to a producer is operational efficiency. For Chevron, this means (a) managing down the cost of steam generation for injection into the field and (b) using information technology to be able to “dial in” the steam at the optimum pressure and temperature to specific locations in the strata of the field—and then recovering that newly flowing oil.

Here, Chevron has reduced its steam:oil ratio (i.e., the steam required, represented by barrels of water, to produce one barrel of oil) from a peak of almost 8.5 in 1988 to just above 2.3 for the first quarter of 2011, according to data from the California Department of Oil, Gas & Geothermal Resources (DOGGR).

|

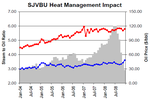

| Chevron says thermal management gives it a competitive advantage. The plot shows the steam:oil ratio for Chevron in blue, compared to other producers (red).Source: Chevron. Click to enlarge. |

Furthermore, according to a preliminary survey by the California Air Resources Board (ARB) in preparation for monitoring and regulating greenhouse gas emissions from the production of oil and gas, combustion emissions represented 82% of the total greenhouse gas emissions associated with oil and gas production in the state in 2007; of those combustion emissions, steam generation represented 42% (6,696,706 MT CO2e)—about 35% of total GHG emissions associated with oil and gas production. Reducing steam generation requirements and optimizing the generation process reduces the GHG overhead associated with the production of heavier oil.

Chevron has already shifted to gas-fired co-generation plants to produce steam and export power to the California grid; it is also working on a solar concentrator pilot in New Mexico that would generate steam using sunlight to further reduce costs and environmental impact of its thermal production process.

|

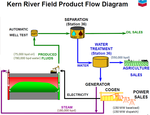

| Current product flow at Kern River field. The water cycle doesn’s require an infusion of fresh water due to the large amounts of produced water from the field. Source: Chevron. Click to enlarge. |

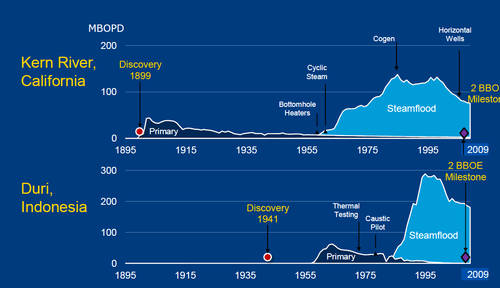

Chevron says that it has about a 70% recovery factor of oil from the aging Kern River field, and is targeting up to 80% recovery, cost-effectively, using these capabilities. Indonesia’s Duri heavy oil field has also achieved an ultimate recovery factor of 70% after employing steamflood technology. PT Chevron Pacific Indonesia, a wholly owned Chevron subsidiary, operates the North Duri Field Area 12 in Indonesia, where Chevron produces nearly half the nation’s crude oil. Chevron is taking its technology learnings from Kern River and apply them to Duri and other major heavy oil fields globally, such as Wafra in the onshore Partitioned Neutral Zone (PNZ) between Kuwait and Saudi Arabia and in the Orinoco in Venezuela. Chevron’s heavy oil interests also include the oil sands in Canada and in the deepwater Brazil.

(The US Geological Survey has estimated a mean volume of 513 billion barrels of technically recoverable heavy oil in the Orinoco Oil Belt Assessment Unit of the East Venezuela Basin Province; the range is 380 to 652 billion barrels. The Orinoco Oil Belt Assessment Unit thus contains one of the largest recoverable oil accumulations in the world.)

|

| Production of heavy oil at Kern River and Duri. Both fields have hit the milestone of 2 billion barrels of oil produced. Source: Chevron. Click to enlarge. |

Background: Heavy oil and steamflooding. Heavy oil is a dense, viscous crude oil with an API gravity below 20°; ultra-heavy oil has a gravity below 10° API. Most heavy oil has a viscosity between 100 and 10,000 centipoise (cp), and does not flow readily in the reservoir without dilution (with solvent) and/or the introduction of heat.

|

| Worldwide heavy oil reserves by country. Source: Schlumberger. Click to enlarge. |

The US heavy oil resource approaches 100 billion barrels of original oil in-place (OOIP), with more than 40% of that in California, according to the US Department of Energy (DOE). Of the total worldwide oil resources of 9–13 trillion barrels, 15% is estimated to be heavy (i.e., 1.35–3.25 trillion barrels); 25% extra-heavy; 30% oil sands and bitumen; and 30% conventional, according to estimates pulled together by Schlumberger.

Most heavy oil recovery is by thermal methods—i.e., heating the viscous oil so that it flows and can be produced—including steam injection and, to a lesser extent, in situ combustion and CSS (cyclic steam stimulation). Unlike CSS—in which steam is pumped directly into the producing wellbore to heat the viscous oil, which is subsequently produced back up through the production well—steamflood producing wells are stimulated by steam injected into nearby injection wells. The steam helps heated oil migrate to the producing wells where it is produced by either natural flow or artificial lift.

|

| The concept of steamflooding. The actual structure of a real reservoir makes it more complex. Source: DOE. Click to enlarge. |

Using thermal recovery processes in heavy oil reservoirs depends largely on capital cost per barrel of steam generation; according to Chevron, steam generation currently represents fully 50% of its operating expenses for the Kern River field.

Oil price volatility has in the past been a significant deterrent to heavy oil project investment by industry, particularly by smaller independent producers, the DOE notes. Thermal recovery has generally been applied to large fields that can achieve higher return on investment due to lower costs per barrel of incremental oil recovered; heavy oil carries a lower market price than lighter oils.

However, while production costs and refining costs for heavy oil exceed that for light oil, Chevron is applying information technology to improve thermal management of the resources to increase the margins and profits of operations.

| Kern River Field current stats | |

|---|---|

| Oil production | 75,000 bpd |

| Water production | 780,000 bpd |

| Steam injection | 180,000 bpd |

| Clean water shipped to agriculture (regulated) | 550,000 bpd |

| Water lease usage | 50,000 bpd |

| Active injection wells | ~700 |

In steamflooding, high-temperature steam is continuously injected into a reservoir; Chevron has been putting steam in the Kern River field for some 50 years. As the steam loses heat to the formation, it condenses into hot water, which, coupled with the continuous supply of steam behind it, provides the drive to move the oil to production wells.

The heated oil becomes less viscous, making it easier to move through the formation toward production wells (although the flow can also miss those wells, Chevron notes). Expansion or swelling of the oil also aids in releasing it from the reservoir rock. The condensed steam cools as it moves through the reservoir and results in what amounts to an ordinary waterflood ahead of the heated zone.

|

| Temperature and viscosity. Source: Chevron. Click to enlarge. |

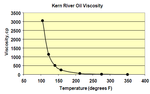

Crude viscosity is temperature dependent, notes Chevron’s Jeff Hatley, with a dramatic reduction in viscosity up to a characteristic temperature that is dependent upon the type of crude (e.g., paraffinic vs asphaltic).

Steam interacts with fluids and rocks, reducing viscosity, creating mobility of the crude and then replacing the crude after it drains out of the reservoir...we experience incredibly high recoveries.

When we use steam, it’s generally in saturated form. That means that the pressure and temperature are directly related. If the reservoir temperature is high, the steam temperature is high ... 60 °F. If the reservoir temperature can be maintained low...then the opportunity to reduce pressure can be obtained. That difference is enormous in steam cost.

So that shape [the curve, above right] to an engineer screams optimization. In the early days of steam flooding, you might be operating all the way [at the high temperature end of the curve]. This opens up the whole concept of heat management, of not just injecting steam and producing oil, but dialing in the steam precisely. That’s Chevron’s heat management practices. It’s about optimization. And when steam cost is the 800-pound gorilla in the process, that is where a lot of technology tends to be focused.

—Jeff Hatley

i-field. Most oil majors and service companies have developed or are leveraging information technology for field management—i.e., the “Digital Oil Field of the Future”. Chevron’s i-field program is its effort to integrate people, processes, technology and information to achieve this transformation of its upstream business.

Chevron initiated a new multiyear i-field program, Integrated Reservoir Management (i-RM) in the San Joaquin Valley to enable efficient reservoir management (RM) and quality decision making for heavy oil assets operating under steamflood enhanced oil recovery (EOR) technologies.

|

| Kern River Field. Click to enlarge. |

Chevron integrated more than 30 years of best practices, disperse data—such as paper well logs and more modern borehole data—and tools within one solution. Throughout the valley, Chevron has more than 15,000 active producing wells, with more than 700 new wells drilled annually, all generating massive amounts of new data to be stored in the databases.

In Kern River field alone, more than 19,000 wells were drilled within its 25 square miles areal extent since discovery in 1899. Currently, the field operates with more than 9,000 active wells which generate more than 1,000,000 data points (tests, measurements, dynocards, etc.) being recorded daily.

Both producing wells and injection wells in the Kern River field are vertical. However, new flowing oil may bypass the vertical producing shaft; similarly, a horizontal injection of steam could prove more effective in the precise heating of a narrow band of oil-saturated sand than a vertically injected plume (although Chevron is experimenting with targeted vertical injection as well).

Vertical steam injection wells are not effective in areas with limited available surface locations, expensive surface locations (swamp, tundra), or for supporting individual, ‘thin’ (~ < 30’) oil bearing intervals. Horizontal wells—both producers and injectors—are needed for these conditions. Horizontal wells have the potential to minimize surface land usage, minimize the extent of surface facilities, and improve the capital efficiency of projects.

Horizontal steam injection is required for developing heavy oil opportunities that cannot be profitably developed using conventional vertical steam injection wells or where horizontal steam injection wells will substantially improve the value of a project. With increasing facility capital cost, new heavy oil horizontal technology becomes attractive as a development alternative for most new thermal recovery projects and for substantial field expansions. To preserve land for surface usage, many are requiring smaller surface footprints that are only achievable through the use of horizontal wells. In summary, new horizontal thermal technology is needed to economically develop the reserves of the future.

—Fram et al.

With that in mind, Chevron is exploring the use of horizontal wells for both injection and production, and established the Horizontal Steam Injection Test Facility (HSITF) in the Kern River field. This facility is used for testing commercial and proprietary devices for improving control of steam distribution along a lateral in a horizontal well. The horizontal steam injection test facility tests the capabilities of a wide range of full-sized downhole completion equipment (tubing and liner flow control devices, tubing/liner and annulus/liner isolation devices) at the surface under precise controlled conditions.

Chevron and the American Petroleum Institute (API) recently hosted Green Car Congress and other media at a briefing in Bakersfield at the Kern River field, paying for travel and lodging.

Resources

-

Andrei Popa, Steve Cassidy, Mark Mercer (2011a) A Data Mining Approach to Unlock Potential from an Old Heavy Oil Field (SPE 144470-MS) doi: 10.2118/144470-MS

-

Andrei Popa, Mark Barrett, Steve Cassidy, (2011b) Programs Enable Operational Excellence in a Challenging Environment, Pushing the Limits of Large Data Transfer for Real Time Monitoring and Surveillance Operations in San Joaquin Valley. (SPE 144469-MS) doi: 10.2118/144469-MS

-

Andrei Popa, Katie Horner, Steve Cassidy, Steve Opsal (2011c) Implementing i-field Integrated Solutions for Reservoir Management: San Joaquin Valley Case Study. (SPE 143950-MS) doi: 10.2118/143950-MS

-

Andrei Popa, Katie Horner, Steve Cassidy, Steve Opsal (2011d) Implementing Integrated Solutions for Reservoir Management: San Joaquin Valley Case Study. (SPE 144468-MS) doi: 10.2118/144468-MS

-

J.H. Fram, J.C. Sims, A.J. Sequera and T.C. Mayer (2010) Addressing Horizontal Steam Injection Completions Challenges with Chevron’s Horizontal Steam Test Facility (SPE 132410-MS) doi: 10.2118/132410-MS

-

DOE fact sheet: US Heavy Oil Resource Potential

-

USGS, (2009) An Estimate of Recoverable Heavy Oil Resources of the Orinoco Oil Belt, Venezuela

© 2004-2013 Green Car Congress